Plastics are, however, an entirely different animal from paper-based substrates. “Paper is forgiving – plastic is not,” notes Ray Prince, senior technical consultant at GATF (Sewickley, PA). “Your latitude is quite small. It does not allow for mistakes. And, it’s much more expensive.” Printing on plastic thus requires careful planning, communication with your suppliers and the patience to learn optimal print conditions through some trial and error.

PROOF IS IN THE PLASTIC

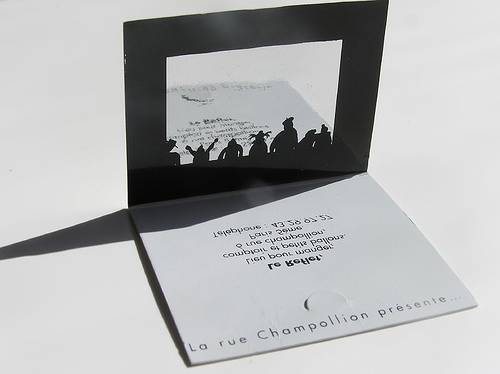

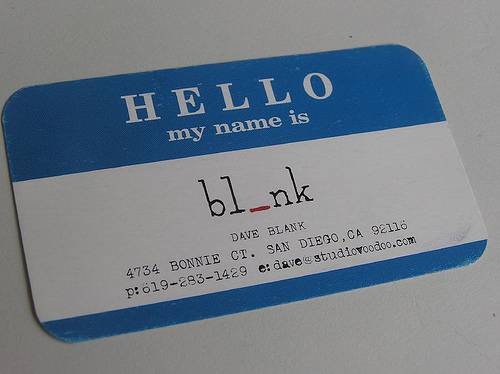

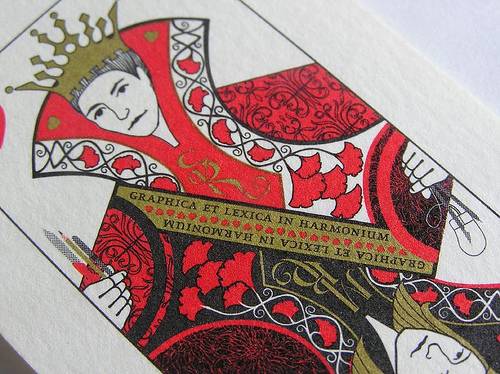

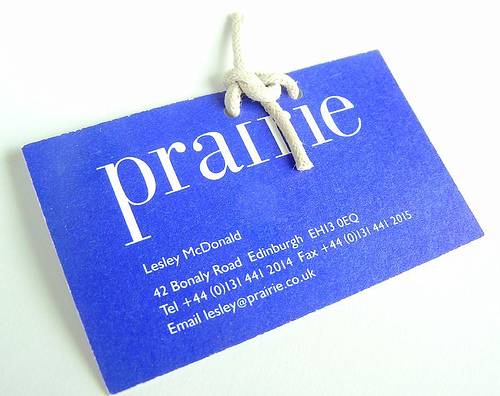

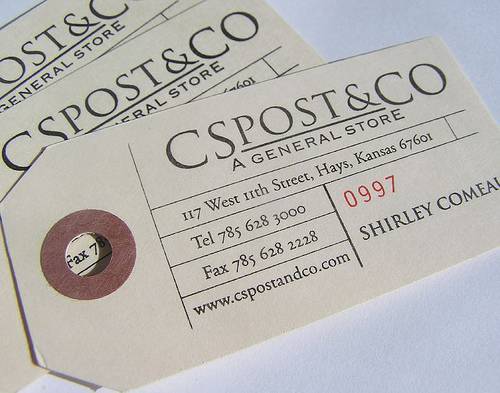

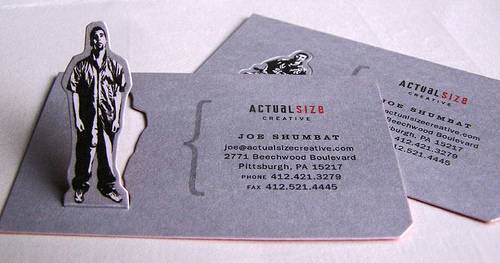

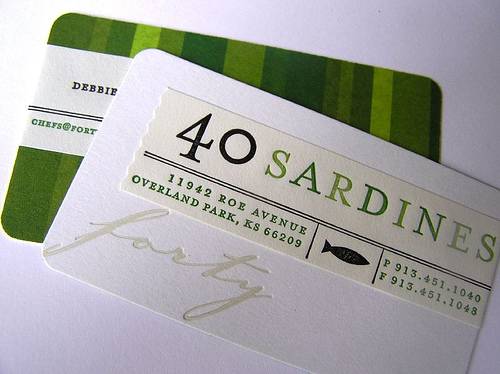

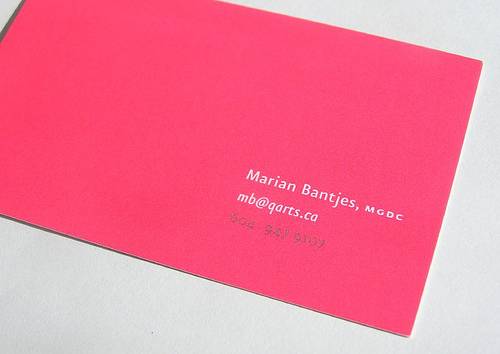

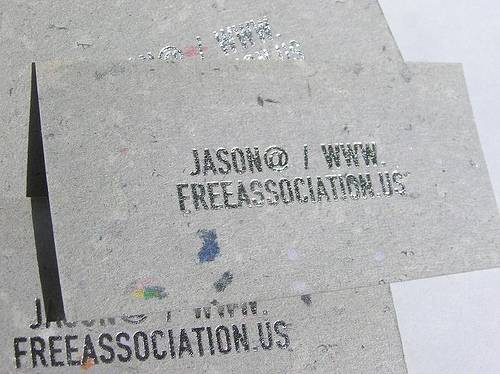

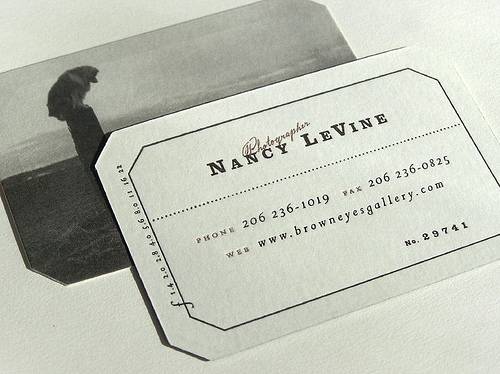

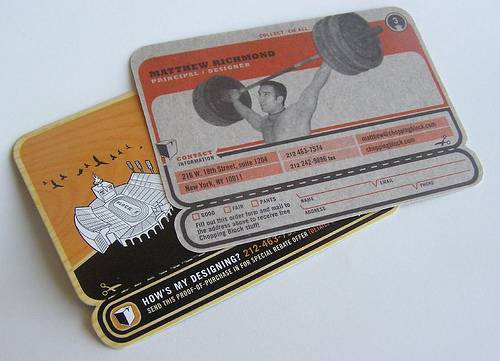

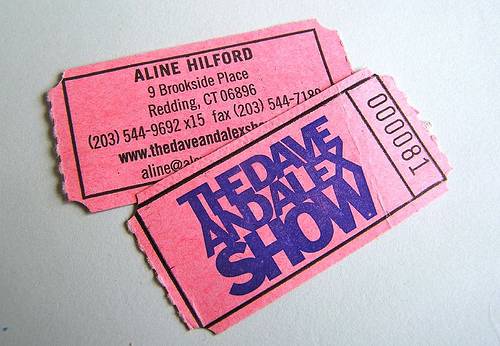

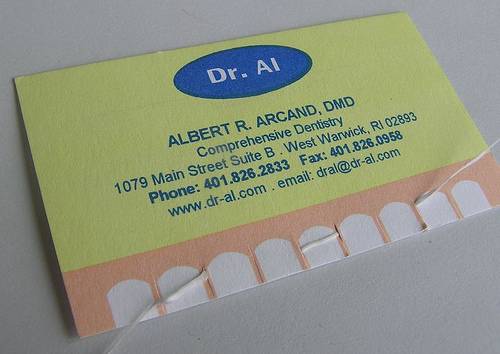

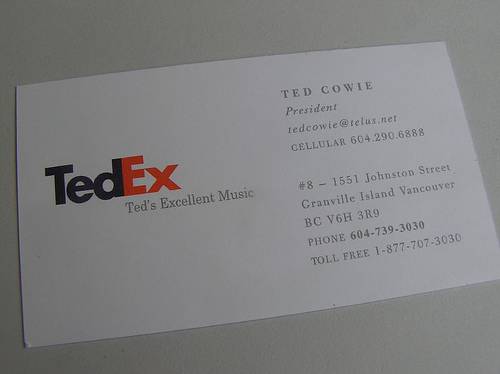

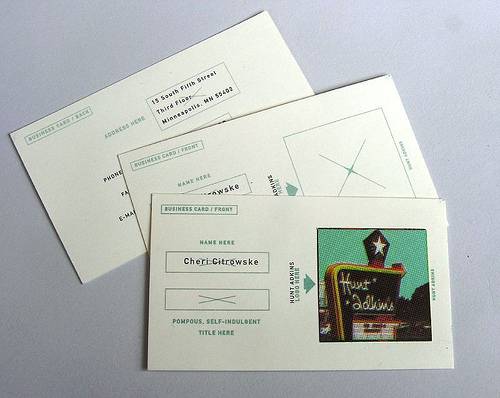

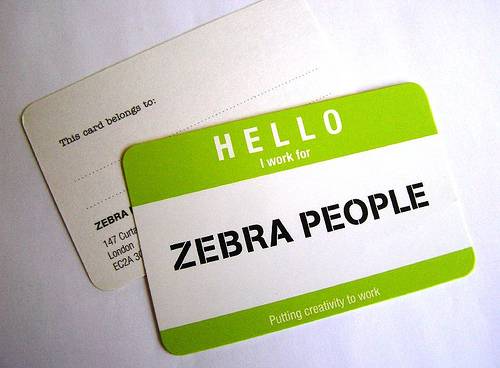

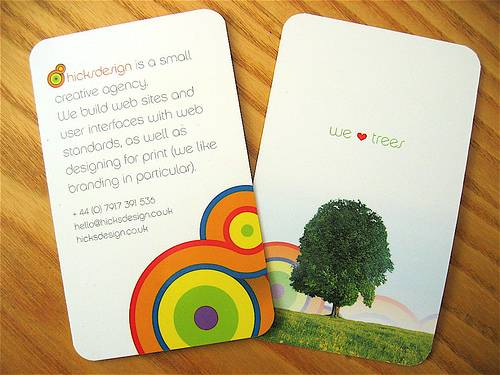

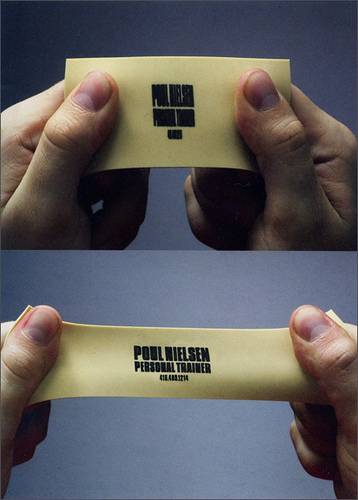

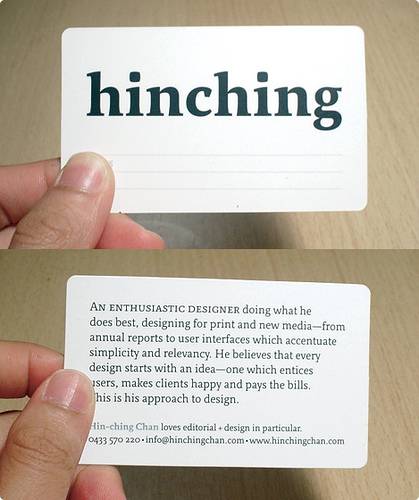

Plastics open up a new realm of products that are either unsuitable for or inferior in paper form. Back-lit displays, outdoor signage and banners, tags, plastic business cards, membership cards, id cards, menus, plastic phone cards, point-of-purchase (POP) displays, labels, window displays and maps are a few of the more popular applications, although many specialty printers venture into lenticular printing and packaging.

“We are seeing growing interest from commercial printers,” notes Tom Leiding, national sales manager at Transilwrap Co. Inc. (Strongsville, OH), a manufacturer of artificial substrates. “It continues to be a niche for them, and it’s becoming more popular because it brings printers a value-added to their arsenal of products.”

Many printers, however, approach printing on plastic as if it’s a matter of switching from uncoated to glossy, when in fact each application demands a customized approach from prepress to the bindery.

Proofing plastic jobs is often a matter of eliminating processes, advises GATF art director David Watterson. “First, you want to proof on the actual substrate. That eliminates a lot of proofing options right off the bat,” he explains. Some of the most popular proofing products include DuPont Imaging Technologies’ (Wilmington, DE) WaterProof; Polaroid Graphics Imaging LLC’s (Bedford, MA) PolaProof; Kodak Polychrome Graphics’ (Norwalk, CT) Matchprint; Fuji Photo Film U.S.A., Inc.’s (Hanover Park, IL) FinalProof; Agfa Corp.’s (Ridgefield Park, NJ) Grand Sherpa and Sherpa; and color keys.

“Even though you may be able to proof on the actual substrate, many proofers use a coating or lamination that can ruin the look of the shiny, reflective or unique substrate,” he continues. “Proofing for these purposes has to be on a per-case and per-process basis.” Watterson suggests looking at your needs, workflow and level of contract-proof requirements. If you’ve never proofed on plastic before, consult with a service provider who has. He also suggests discussing the challenging aspect of proofing on plastic with customers to prepare them for what might be an arduous experience.

DETERMINING THE DYNE

One of the first steps in printing on plastic is to determine the dyne level—or surface energy—of the substrate on which you’ll be printing. “In conventional printing, inks bond to the substrate by surface-tension potential,” notes Richard Moehring, vice president of sales at Carton Sales Co. Inc. (CSC) (Sugar Land, TX), a 90-employee printer specializing in high-end retail packaging. “That surface-tension potential is more consistent with paper.” With plastic, the exec explains, the dyne level tends to vary greatly.

There are different methods to test the dyne level, from dyne pens and markers to cotton swabs dipped in dyne-test solutions. “The felt-marker method is one of the worst,” notes Prince at GATF. “Some markers become contaminated quickly. You can use them about three times and that’s it – they start giving false readings.” Prince recommends using the latter approach, which involves dipping a cotton swab in a dyne solution, and then marking the substrate.

It is crucial that the dyne level measure between 38 and 50, with 40 being the ideal. “If it’s below 38, the ink won’t dry and will peel off,” notes Dennis Jaynes, director of quality control, safety, security and training at Jet Lithocolor Inc. (Downers Grove, IL), a $40 million high-end printer that specializes in artificial-substrate work. “If it’s above 50, you’ll have static problems and won’t be able to get the job through the press.” Substrates with dyne levels lower than 38 are still printable, but will need to be corona-treated to ensure ink adhesion.

Prince recommends that, for each job, you acquire a pre-shipment sample of 50 8 x 10-inch sheets of the exact lot number of the substrate being printed on, test the dyne level and then give a sample to your ink manufacturer so that it may formulate a suitable ink.

“This last item is what most people fail to do, and where they can get into the biggest problems,” notes Prince. “All of a sudden, you can have 90,000 sheets sitting out there, at $2 a sheet, and they won’t dry.”

CUSTOMIZE YOUR INKS, CHEMISTRY

Printers with UV capability have greater latitude when printing on plastic (see “The UV approach to plastics,” p. 44), and avoid the drying problems that frequently plague plastic printing. For conventional printers, customization is key.

To ensure proper adhesion, inks need to be formulated specifically for printing on plastic. “Typically they need to be free of nonreactive components – anything that isn’t going to become part of the final ink film needs to be left out, or it will keep the ink film soft,” explains Byron Hahn, technical director at Braden Sutphin Ink Co. (Cleveland), and speaker at last year’s GATF Printing on Plastic, Film and Foil Conference. The exec notes that in plastic inks, the dryer-catalyst package needs to be formulated for adverse conditions of high moisture content and low oxygen level.

The amount of chemistry used also directly impacts drying. “What probably gets most printers in trouble is trying to use the same amount of fountain solution on plastics as they do on paper,” notes Transilwrap technical service engineer Jerry Krupa. “Cellulose-type paper is very absorbent. Plastics won’t absorb any water.” Hahn recommends an ink that will perform with minimal water in the feed and in the press, because the fountain chemistry interferes with the oxidation process.

Krupa also recommends performing the makeready on the substrate, rather than on paper. “If you do it on paper stock, your ink and water balance will be incorrect,” he explains. “As soon as you introduce plastic, the setting will be all out of whack because it was balanced for paper.”

FASTER DRYING WITHOUT CHEMISTRY

A new ink technology introduced at Print 01, Just Water Technology from Kustom Group (Florence, KY), holds promise for printing on nonabsorbent substrates. The ink is said to operate with no fountain solution, utilizing only plain tap water (in some applications, a small amount of etch is desirable). Kustom Group licenses its technology to several ink companies. According to vice president of sales and marketing Jim Volz, six have developed products. Midwest Ink Co. (Broadview, IL) has been the most vocal of the group, with several printers currently using its H2O product (see “Sheetfed-ink update,” July 2002, p. 32, for more details).

Midwest Ink vice president Joseph Hannon explains that its H2O product cures faster on stock because the lack of chemistry in the ink speeds up drying. He notes that a press’ dampening system and the press operator’s skill level will impact this; however, GATF’s Prince reports that jobs printed on plastic with H2O ink are experiencing drying times of around four hours, compared to 24 to 48 hours with other inks.

For printers running chemistry, recommendations to optimize drying include running shorter lifts of two inches to three inches to minimize compression and prevent offsetting, and using approximately 50-micron-particle spray powder to allow more air in between sheets. To avoid register problems, it’s crucial to acclimate stock to pressroom conditions for at least 24 hours; in the winter, at least 48 hours is recommended, as pallets of stock tend to warm very slowly from the outside in.

STATIC CONTROL

Plastics can accumulate an alarming amount of static charge—the fact that, by rubbing a balloon on your head, you can get it to stick on a wall testifies to this. And, some plastics in particular—thin vinyls, for instance—are especially prone. “You get into some thin vinyls, and I don’t care how many static guards you have, you are going to electrocute your press operator at the delivery,” quips Moehring.

Prince offers three guidelines for static control: First, the press should be heavily grounded. Second, temperature and humidity control in the pressroom are mandatory – Jet Lithocolor, for instance, keeps its air-conditioned facility between 70aF and 76aF, and relative humidity between 30 percent and 50 percent. Third, utilize anti-static devices on the press itself for static removal.

According to Transilwrap’s Krupa, there are two different approaches to static control – passive and active. Passive methods incorporate such devices as tinsel, static string and static bars, which are put in contact with a substrate while it’s running through the press to neutralize the charge. Active devices, such as ionized air blowers or ionized air curtains, literally force ionized particles into the sheet or into the stack.

“You can pinpoint the ionization and actually get it into the top few sheets of the stack, whereas the press-supplied air typically is not ionized and when you have static, doesn’t do a good job of helping sheets separate,” Krupa explains. “An ionized air curtain will, and it can be strong enough to force air between the sheets as they’re being picked up.”

Krupa notes that active devices typically cost less than $1,000; it’s important, however, to have an air compressor that is powerful enough to supply the device adequately. Manufacturers of active static-control equipment include SIMCO Industrial Static Control (Hatfield, PA); Meech Static Eliminators U.S.A. (Richfield, OH); Tantec Inc. (Schaumburg, IL); and Exair (Cincinnati).

FINISHING THE JOB

When finishing, plastic is surprisingly versatile. “Depending on the material, you can almost do as much – if not more – finishing, including diecutting, folding, taping, riveting, embossing and foil stamping,” notes Moehring at CSC. “But each one brings a really particular, unique challenge to the converter.”

For instance, the exec notes that something as simple as running a printed plastic sheet through a power knife to size it could break the surface tension at the edge of the sheet, causing the ink to chip and fall off. This can be prevented earlier in the production process by ensuring that your inks are adequately bonded to the substrate; a simple cross-hatch, nickel-rub or tape test can determine the level of adhesion.

Jaynes at Jet Lithocolor advises determining how much resin is in plastic before punching it. Some plastics punch cleanly, while others leave a residue. In addition, certain substrates require different levels of heat to fuse them together. Jaynes suggests checking the plastic’s receptivity to adhesives, heat and pressure before processing it.

When cutting plastic stock, the knife angle and clamp pressure may need to be adjusted. Krupa says that, when diecutting, it’s important to keep the die sharp – if not, angel-hairing can result. Some material, like polystyrene, doesn’t score well. Others, like vinyl and polypropylenes, do. Ultimately, each application and plastic is unique, so consult with the media vendor for specific finishing guidelines.

FROM GRAPHIC ARTS TO SCIENCE

The old mantra of “do your homework” applies doubly when printing on plastics. Those interviewed for this article note that most printers get into trouble by neither researching nor consulting with those who know how to optimize printing on plastic – from ink and fountain-solution suppliers to stock vendors.

“Printing on artificial substrates is not like printing on anything else,” observes Jaynes at Jet Lithocolor. “It moves from graphic arts to graphic science, because you have to know the physical properties and characteristics of all of the ingredients.” The quality-assurance manager says those new to printing on plastic should anticipate a long and potentially expensive learning curve.

“[Printing] is kind of like flying an airplane,” Jaynes observes. “When you’re landing a plane, it’s like controlled chaos, because you’re falling out of the sky but it’s in a set pattern. When you print, you’re squeezing, pulling, printing, and throwing ink and water on a sheet, and that’s chaos too, but it’s controlled. If it’s controlled chaos and it comes out right, you have a good product. If it doesn’t, then you have to call the fire truck.”

The UV approach to plastics

Printers that dedicate a sizeable portion of their jobs to plastic should consider getting into UV. “It’s not inexpensive, but for people looking for that impact, UV allows different print techniques, substrates, and combinations of technique and substrate,” notes Dan Frederickson, president of UV Color, Inc. (Roseville, MN), a 220-employee, high-end printer specializing in phone and gift cards, point of purchase (POP), and specialty packaging on foils and plastics.

“UV definitely brings more volume to the equation,” notes Tom Leiding, national sales manager at Transilwrap Co. Inc. (Strongsville, OH), a manufacturer and distributor of plastics for offset. Leiding notes that UV printers can produce runs upwards of hundreds of thousands of impressions, whereas conventional printers are typically limited to runs below 100,000 impressions.

Curing issues

UV Color runs plastic jobs on any one of its commercial sheetfed presses, which include a Komori (Rolling Meadows, IL) halfsize six-color unit; six- and seven-color MAN Roland (Westmont, IL) 700 fullsize presses; and a KBA (Williston, VT) Rapida 105 eight-color, fullsize press with an anilox coater and extended delivery, which make it ideal for applying very smooth coatings. Frederickson’s previous company, Color Sells, was reportedly one of the first printers in the country to pioneer UV printing on plastics.

“Getting the right amount of curing is very important – you don’t want to undercure or overcure,” Frederickson notes. “Any time you hit the stock with too much UV energy, it can become brittle, and you can lose the functionality.” In addition, the exec explains that, when run through a UV dryer, clear polypropylene turns a bright yellow. Fortunately, the effect completely dissipates after a period of time.

Carton Sales Co. Inc. (CSC) (Sugar Land, TX) entered the plastic-printing market as an aftermath of implementing UV printing. “The decision wasn’t ‘Do we want to print on plastic,’ but rather, ‘Do we want to have a superior printing system that will allow us to put a high-gloss finish in line,'” explains Richard Moehring, vice president of sales. The 43-year-old company began as a printer and converter of paperboard packaging for folding-carton and POP displays, and today offers products from binders to high-end retail packaging.

“Just because you have UV-printing capability doesn’t make work any easier,” Moehring cautions. “When you print on plastic, especially when using UV lamps, the heat will modify or shrink the plastic somewhat, regardless of thickness. So, if you’re putting down one color at a time, you’re going to have big trouble,” he says. The exec suggests printing on a press capable of putting all colors down at once to avoid registration problems and distortion. CSC has a six-color, seven-station Heidelberg (Kennesaw, GA) CD 102; an eight-color, nine-station fullsize press; and a 10-color, fullsize Speedmaster 102 perfector.

‘Cold’ technology

Ray Prince, senior technical consultant at GATF (Sewickley, PA), recommends using the lowest-temperature UV system possible when printing on plastic. One “cold” technology currently being offered is inert UV, from Eltosch North America (Brookfield, WI). Here, oxygen – which inhibits UV ink from drying – is replaced with nitrogen, which enables curing at a much lower temperature. Prince notes, however, that inert UV is currently relegated to specialty printers who print exclusively on plastic.

Ink manufacturers are also tailoring their UV products to plastic printing. At Graph Expo, Flint Ink (Ann Arbor, MI) introduced its Matrixcure-NP UV ink for nonporous substrates.

Plastics 101: plastics terminology

Never mind that the actual process of printing on plastic is often fraught with complexities – the substrates themselves can be a major area of confusion for printers.

“People will call and ask for ‘acetate,’ which is a generic plastic name that hasn’t been used since the 1960s and 1970s, when acetate was the most popular product,” says Tom Leiding, national sales manager for Transilwrap Co. Inc. (Strongsville, OH), a manufacturer of artificial substrates for the graphic-arts industry. “They even refer to plastic sometimes as ‘paper,’ i.e., ‘I need that paper stuff that doesn’t break.’ New printers coming into the arena are more familiar with the paper industry, and that’s not the jargon we use in plastics.”

The major plastics currently used in litho printing include:

Polystyrene

This medium is used for such applications as point-of-purchase (POP) displays or signage, shelf wobblers and danglers, as well as gas-station pump toppers. Transilwrap product manager Brad Braunreuther explains that styrene is an affordable choice for applications requiring a substrate a step more resilient than paper.

Polyvinylchloride (PVC)

PVC, also generally referred to as vinyl, is offered in flexible and rigid forms. Flexible PVC is used for such jobs as static-cling decals, whereas rigid is incorporated as signage. For applications requiring outdoor durability or high tear resistance, PVC is considered to be a step up from styrene.

Polyethylene

This medium, also available in low-density, flexible and high-density, rigid forms, is often used for banner films.

Polypropylene

A durable, UV-resistant substrate used for outdoor applications and POP signage.

Polycarbonate

According to Braunreuther, this medium is often used for automotive decoration – for instance, in a car’s speedometer cluster – and used for applications requiring a high chemical resistance, such as on gas pumps.

Polyester

This substrate is frequently used for transparencies, in such products as biology schoolbooks.

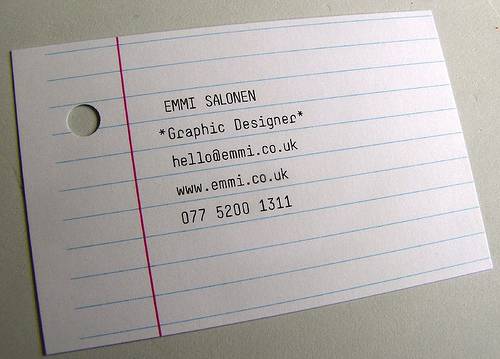

Synthetic papers

Usually composed of polypropylene extruded with fillers through a die, stretched thin and then surface-treated to enhance printability, synthetic papers are ideal for applications such as menus and brochures.