The simple full colour plastic card is a valuable asset to any businessman or professional. It is your own personal advertisement and calling card. The full colour plastic card is not just for the salesman, however, but also for anyone in business. The full colour plastic card can be printed in various forms in addition to the common black on white full colour plastic card.

Full colour plastic card printing has moved online along with much of the rest of the world of business. You can purchase software that enables you to print your own full colour plastic cards. Full colour plastic card printing has become a popular choice for a home based business.

Among the various types of cards that can be printed are the magnetic cards and plastic cards. Both of these take printing beyond the simple card stock of the past into a new and exciting area. Plastic cards printing is a more expensive process and you can expect to pay more for these exotic cards than normal cards. The plastic card looks very much like a normal card, but the plastic material used for stock yields a card that is durable and flexible. They will long outlast the normal card stock.

Magnetic cards are another option that has grown popular among business men looking for something new and different. The card is printed on plastic stock with a magnetic backing that allows it to be easily hung on the refrigerator or other metallic service.

The folded full colour plastic card is another option. The advantage of the folded card is a much larger message space. In addition to the normal contact information printed on the face of the card, additional details about your business or professional service can be printed on the inside of the fold.

Regardless of the printing method, the stock used, or the size and style, some elements of full colour plastic card printing remain constant. An effective full colour plastic card must contain accurate and complete contact information. This includes name, address, telephone number, and email if appropriate. An effective card also uses some element that makes it stand out among other cards. This can be color, or it can be raised or embossed printing. It might mean a distinctive logo or some eye catching artwork. You are trying to make the card stand out among thousands of other cards, and must take the extra steps to insure that this happens. The printing options available have made it fairly easy to find a way to make your card stand out from the crowd.

Natalie Aranda writes about marketing. Among the various types of cards that can be printed are the magnetic cards and plastic cards. Both of these take printing beyond the simple card stock of the past into a new and exciting area. Plastic cards printing is a more expensive process and you can expect to pay more for these exotic cards than normal cards. The plastic card looks very much like a normal card, but the plastic material used for stock yields a card that is durable and flexible. They will long outlast the normal card stock.

Many UK business owners who provide products and services to the public offer some type of plastic credit card or plastic loyalty card to their customers. In this article, we’ll present some basic information about plastic card printing and how it can help your business.

How Can I Use Plastic Cards in My Business?

Custom plastic cards are a wonderful and cost effective “perk” that increases both goodwill and sales. To get started, you’ll need a specialized piece of plastic cards printing equipment and a computer to attach it to. Once you’ve gotten your hardware, we’re sure you’ll find many other uses for your plastic cards printing machine. For example, you might want to consider employee ID cards, personalized gift cards or visitor badges in addition to the cards you give to your customers.

Who’s Using Plastic Card Printers?

So, who’s using plastic card printing machines? Here are just a few headlines from various Internet sources:

“Self-Printed Gift Cards Are In Style at shopLAstyle.com”

“The Store” Provides On-the-Spot Loyalty Cards to Shoppers with Card Printers”

“Card Printers a Clear Winner for Qatar Airways Frequent Flyer Program”

“Award-Winning Funeral Home Prints Its Own Commemorative Plastic Cards”

“Promotional Products Company Uses Printer to Create Custom ID Cards for Clients”

Features and Pricing for Plastic Card Printers

Cards like plastic membership cards are easy to customize. You can add a magnetic stripe, bar code or OCR lettering. You will have complete control over the custom plastic cards printing process. Imagine being able to instantly design a striking plastic card, complete with your logo and custom artwork. Basic plastic cards printers are surprisingly affordable, with prices starting at about $1200 US (£810 GBP). Plastic cards printing technology is used worldwide for an amazing variety of applications. Shouldn’t your UK business it them as well?

How to Make Hologram Sticker?

step1. Make hologram master origination (Master origination shooting system, 2D/3D or Dot-matrix)

step2. Recombine Dot-matrix master in size of160mm*160. 2D/3D master doesn’t need recombination. (Recombiner)

step3. Copy operation nickel shim from hologram master origination(Electronic Forming Machine)

step4. Emboss metallized PET film, transparent film(Narrow Web Hard Embosser)

step5. Laminate silicon liner together with embossed hologram film(Lamination Machine)

step6. Die-cutting, Slitting (Die-cutting Machine)

How to Make Hologram Hot Stamping Foil by Hard Embosser?

step1. Make hologram master origination (Master origination shooting system, 2D/3D or Dot-matrix)

step2. Copy operation nickel shim from hologram master origination(Electronic Forming Machine)

step3. Emboss hot stamping foil which is without hot melt adhesive(Hard Embosser)

step4. Coat hot melt adhesive(Hot stamping foil coating machine)

How to Make Transparent Holographic Film and Silver,Red, Green, … Holographic Film ?

step1. Produce small pcs customized design hologram master(Master origination shooting system, 2D/3D or Dot-matrix) .

step2. Recombine small master to big master upto size of 1500mm*600mm. (Big Recombinaiton Machine)

step3. Copy big size nickel master shim(Electronic Forming). We have around 80 general design master upto size 1500mm*600mm.

step4. Eemboss transparent pre-coated BOPP film, PET film, PVC film. Then you get transparent hologram film for packaging. Or to emboss pre-coated with color layer to produce silver, red, green holographic packaging film. (Soft wide web embosser)

step5. Vacuum Metalizer to metalize transparent hologram film. Then you get silver, red, green holographic packaging film. (There’re several good quality Vacuum Metalizer suppliers in China)

We also can use soft embosser to produce wide web hologram hot stamping foil with Vacuum Metalizer, Coating machines.

Brief of how to make hologram sticker.

Briefly discussed below is the process of making a typical two-layer ” Embossing Reflection Hologram “, by far the most common and cost-effective hologram , with two common sub-types, namely the two layer hologram (with a background image and a foreground image) and the three layer hologram (with a background image, a middle ground image and a foreground image).

Our holograms are made on a large stable table with a laser, lenses, mirrors and other optics. The table is composed of a large mass resting on a vibration isolation system to dampen any movement. Since the hologram records light waves, movement as small as one-quarter of a wavelength of light will ruin the hologram.

To make a hologram, the laser beam is split into two beams. One part of the laser beam is directed by mirrors and spread by lenses to illuminate the object. The laser lights the object, then bounces off and hits the holographic film or plate positioned in front of the object. The other portion of the laser beam, called the reference beam, is directed by mirrors and lenses to evenly illuminate the film. Where the two portions of the laser beam meet at the film, they interfere constructively and record the hologram.

This “constructive interference” of laser light’s waves is similar to the ocean’s waves traveling onto the beach. When two waves meet just right, their collision enlarges or amplifies their size. In holography, this wave amplification exposes the holographic film.

After exposure, the holographic film is developed, similar to black and white photography. After processing and drying, the hologram is ready for viewing. This series of steps results in a laser-viewable “Master” hologram.

White-light viewable holograms are created in a two step process. First, the laser-viewable Master is holographed. Then, a second hologram is made from the projected pseudoscopic image of the Master. This hologram can be reconstructed – viewed – in white light. The section on “Lighting Instructions” explains viewing a white-light hologram.

Lighting Instructions

A light is needed to illuminate a hologram. A hologram is illuminated by shining the light at the center of the hologram. For ease of viewing, this angle is usually about 45 degrees from the center of the vertical hologram to the light source. This lamp should be at least four feet above the hologram for the best results.

For best clarity, there should be no other lights striking the surface of the hologram.The quality of the light source that illuminates your hologram is very important. The sharper the light source, the sharper the image in the hologram. We recommend a light that uses a 12 volt, 50-75 watt MR-16 quartz halogen bulb.

Another light which works well is the Phillips Master Line, 60 watt PAR-16, narrow spread. These lights can be purchased at most lighting stores. The light should be at least four feet away from the hologram; and shine on the hologram from above at an angle of approximately 45 degrees. Reflection holograms use front lighting. Transmission holograms are illuminated from behind.

Design / Artwork / Origination

Working with you, our graphic team is going to transform your ideas into hologram by developing them in a best way. Designing marvelous visual effects and multi dimensional graphics with color and action unity is possible by using advanced computer techniques.

Artwork file in Corel Draw or Illustrator format is best. Artwork in Corel Draw file can be used for Master Origination Mold(nickel mold) shooting directly. Please save file in Corel Draw version 8 file. The Corel Draw artwork file should be converted into curves. So we can open it. Adobe Photoshop file, JPG, GIF, is ok, but not the best solution.

Mastering

Prepared model work is sent to hologram laboratory. Our expert physics engineers in their fields create Master hologram on a special sensitive emulsion by combining necessary photographic and holographic elements. As it happens in all holograms, this multi dimensional image is recorded by using laser beams and sensitive optical techniques.

Exposing “the positive” of each layer, one after the another, to laser light with the aid of specialized imaging devices such as specialized lenses and mirrors and recording the same on a surface of an ultra clean, photo sensitive and specialized glass plate, to originate “the Glass Master”. At the end of this intricate and time-consuming process, the original two dimensional image of the artwork gets “transformed'” into a “three dimensional” impression on the surface of “the glass master”, called the hologram. The hologram will diffract the seven colours of the spectrum (colours seen in a rainbow) and will produce “the depth effect” or the three dimensional (3D) effect, when it is viewed from different angles under any type of natural or artificial light, thereby giving it an extraordinary visual appeal. During holographic recording, secret information (e.g. code number) can be recorded and concealed in one of the layers of the hologram to make it machine readable only (that is, under special lighting conditions and with the aid of special viewing instruments) in order to impart the inimitable “optical security feature” to the hologram.

Electroforming

The laser beams that are loaded on master plates are transferred to the electroformed metal plates with the aid of chemicals. Transferring the multi-coloured, three-dimensional impression of the hologram from the surface of the glass master to the surface of a nickel plate to create ” the nickel master “. (After this, the glass master cannot be used any further and has to be discarded.). By the same process and from ” the nickel master “, additional nickel plates, also called ” shims ” are prepared for ultimate use in the embossing machine for mass production.

Embossing

Stamper shims are mounted in embossing machines. Transferring the multi-coloured, three-dimensional impression of the hologram from the surface of the shim to the surface of very thin, metallised polyester film roll, through optimal application of heat and pressure. A special chemical coating known as “Tamper Evident Coating'” on the base of the polyester film imparts an important additional security feature to the hologram, to detect any attempt at its unauthorized removal from the surface of a product or of its packaging or of a document.

Adhesive-coating and lamination: ( only for pressure sensitive label only )

The ” embossed ” roll is continuously coated on its reverse with a water-based / solvent-based pressure sensitive adhesive and dried and is thereafter continuously laminated with the silicon-coated surface of the release paper to make a laminated roll.

Die-Cutting

After lamination, the laminated roll is then duly in the size and the shape required by the customer by a very specialized automatic die-cutting machine. For jobs required in Spool Form the laminated rolls are slitted as per size. Holograms in Sheet Form are best suitable for manual affixations while Spool Form for automatic affixations.

Removal of the un-embossed portions of the metallised polyester film from and side-trimming of each sheet bearing several pieces of the hologram to make the sheet uniform in size and facilitate removal of holograms, one by one from the surface of the sheet.

Slitting(ifin roll) and packaging

Slitting sticker in roll format or cutting into panels. The sticker sheet will be packed 200 sheets one bag. The holograms are then finally passed through the quality control department, where each and every property of the hologram is thoroughly checked and finally these holograms are counted, packaged and shipped

|

Every Industry and any industry can use the Holographic products to enhance the image of their brands in the market as an genuine and authenticated brands. They are used for attractive product packaging, security applications (they are almost impossible to counterfeit), fancy gifts, etc. Holograms are new media of 3-D art, registration of priceless artifacts, etc. They are also used in new technology aircraft, automobiles, etc. A few leading companies are also working on Holographic video and TV systems. For your quick reference, some of the industry segemnts where Holograms are used very frequently are as follows:

In display holography ,the advent of pulsed lasers has made it possible to capture images of plants, animals and humans as well as inanimate objects. Holographic packaging materials have become popular and cheap. Security: The use of holograms on credit cards and bank-notes has reduced the opportunity for forgery Interferometry: If a “double exposure” hologram is made of an object before and after the object is subjected to stress, the change in the shape of the object due to that stress is recorded as a series of light and dark bands. In industrial situations this can be used in component testing and quality control. Medical records: Medical, dental and other records can be made both for teaching and for documentation. Measurements: Particle physicists make holographic records of bubble-chambers from which accurate measurements can be made. Display of artifacts: Many museums have made holograms of valuable articles in their collections, both for insurance purposes and to check for deterioration. In the former Soviet Union exhibitions of holograms of national treasures were sent to remote areas, enabling people to see and appreciate their national heritage without the necessity of travelling to major museums in Moscow or Leningrad (St. Petersburg) Holographic Optical Elements (HOEs): If a hologram is made of a lens, mirror or other optical element, it acts in the same way as that element. HOEs can be used, for example, in bar-code readers

|

|

|

|

|

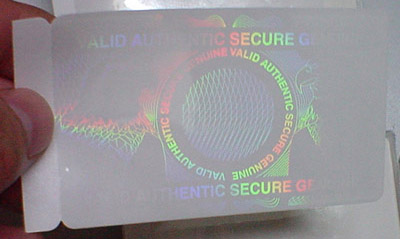

Transparency Hologram ID Overlay

Transparent hologram Overlays for I.D. Cards using a transparent hologram film overlay on a digitally printed ID card protects the inks from excessive abrasion and wear, which extends the card life and enhance the security of your ID cards. The holographic overlay prevents alterations to the ID card information and combats copying or duplicating the ID card. The overlays presented here are “peel and stick” transparent labels which are manually affixed after the ID card is printed. The size of the overlay is slightly smaller than a standard PVC ID card.

Transparent hologram Overlays for I.D. Cards using a transparent hologram film overlay on a digitally printed ID card protects the inks from excessive abrasion and wear, which extends the card life and enhance the security of your ID cards. The holographic overlay prevents alterations to the ID card information and combats copying or duplicating the ID card. The overlays presented here are “peel and stick” transparent labels which are manually affixed after the ID card is printed. The size of the overlay is slightly smaller than a standard PVC ID card.

Clear ID Holograms (Hologram Overlays, Holographic ID Overlays, Clear Holograms) made for ID Cards protection against fake ID cards and cheap Identifications. Transparent ID holograms are indeed transparent holograms and do not abstract the image on ID cards and you can see its Hologram image. ID Holograms are specially sized for ID Cards (Identification Cards) and are pressure sensitive, self adhesive holograms. Just remove paper liner to activate adhesive and apply ID Holograms over your ID cards!

Transparent Hologram ID Card Overlay is transparent, self adhesive labels for use over identification cards, employee badges, and any other cards subject to tampering and/or forgery.

Custom Holographic Origination Overlays:

An overlay with a custom origination of your company name/logo offers the most security for your ID cards. After creating a custom security-grade origination (dot matrix or 2D/3D) for your company/organization, the design is registered with the IHMA global registry. The overlay is constructed in one layer. The hologram is embossed on 25 micron, 50 micron and 100 micron thick special polyester film. After embossing, a permanent acrylic adhesive is applied over the hologram. The overlay is then die cut to size. Total thickness is 30 micron (20 micron polyester + 10 micron adhesive). This product is available in “peel & stick” labels for easy application.

Standard and custom pouches are offered with the following features:

1. Material type: typically 4/6 (40% film /

60% hot melt adhesive) = 100 micron thickness.

2. Material thickness: 37 micron, 50 micron, 70 micron and 100 micron

3. Sizes: standard credit card, driver licenses, business card, military card , luggage tag, jumbo, custom sizes

We produce holographic label, holographic film, holographic cards, holographic gift and sell mastering system, electronic forming machine, hologram embosser(including soft embosser and hard embosser), gluing (adhesive) machine and die cutting machine.

Hologram labels options:

The hologram labels can have up to 3 different layers.

The ordinary hologram labels will show different shining colours when looking from different angels.

The dynamic hologram labels have an additional dynamic effect which look like moving around when turning.

The labels can be tamper evident for secure usage (self destroyed when peeling off).

The background colour will be either silver or gold.

Turnaround time 12-15 days.

|

STYLE |

SIZE | 500 | 1,000 | 5,000 | 10,000 | 20,000 | 50,000 | 100,000 |

|

Ordinary Hologram labels |

<2 square cm | $350 | $350 | $400 | $450 | $530 | $650 | $900 |

| <4 square cm | $350 | $360 | $430 | $490 | $590 | $760 | $1,000 | |

| <7 square cm | $350 | $370 | $460 | $520 | $660 | $880 | $1,100 | |

|

Dynamic Hologram labels |

<3 square cm | $440 | $450 | $530 | $660 | $830 | $1,010 | $1,300 |

| <5 square cm | $440 | $470 | $590 | $760 | $950 | $1,200 | $1,500 | |

| <7 square cm | $440 | $490 | $630 | $860 | $1,080 | $1,360 | $1,700 |

Various types of materials are used to protect plastic cards from abrasion, wear, fading. Alternation, and duplications. Overlay varnishes and laminate patches are the most common materials used to enhance card durability and security.

Card durability has to do with how well the card withstands various forms of environmental stress. They include resistance to abrasion, such as passing the card through a magnetic stripe or bar code reader, protection from image fading when exposed to sunlight, and resistance to damage when immersed in water or exposed to chemicals.

Another important factor in applications such as drivers licensing is resistance to tampering, alteration, and/or replication. With the use of protective materials such as laminate patches with holograms, cards can be constructed to eliminate the potential of tampering and alteration.

Card security means that the card can be verified for authenticity. Techniques include the application of overlay varnish or overlaminate materials with hologram images. Use of these materials in constructing cards makes replication by anyone without access to the custom hologram image materials virtually impossible.

Overlay varnishes provide card protection, but have a much shorter life span that laminate patches – and offer very little security (with the exception of some hologram varnishes). Varnishes are not a solid covering and have multiple tiny holes in the surface, which allows the dyes to be drawn away from the card. This will cause the image on the card to blur and fade due to UV light, shift in color, or just wear away. The life expectancy of a plain plastic card is up to 2 years.

Laminate patches offer better protection than plain varnish, for both security and life expectancy. A patch laminate is, as its name implies, a polyester patch that is applied to the surface of the card after printing. Laminate patches, most often either .6 or 1.0 mil thick are applied via a hot roll laminating station. The life expectancy of a plastic card with a laminate patch is up to seven years.

Quick access to:plastic card | pvc cards | plastic card printing | plastic card company | card print |

plastic card factory | full color plastic card | RFID card | loyalty cards | Photo ID Cards | plastic business cards | Smart Cards | Die Cut Cards | clear frosted Cards | memership card | Gift Cards | Metal Cards | Blank Plastic Cards | Paper Cards

Darren Cottingham presents the case for plastic business cards. They could be that little extra branding boost that makes the difference.

Lesson number one in Japanese business card etiquette: When you receive another person’s card (or ‘meishi’ in Japanese), make a show of carefully examining it for around five seconds, and then make a positive remark about it. Do not shove it in your back pocket, write a note on it, or sling yours to other people across the boardroom table like you’re skimming a stone on a placid lake.

A business card in Japan is a ceremonial opportunity; in New Zealand it’s simply a functional set of contact details and a reminder of the company’s logo. Unless, that is, you have an exquisitely crafted plastic card that makes use of transparency and multi-layered colour. Personally, I’ve only twice had someone take my card and not acknowledge that it was something different – it’s a talking point, and I’m proud of handing my card out in all circumstances. So do plastic cards have the longevity of jeans, or are they simply a fad destined to go the way of Hello Kitty wedding towels?

First impressions

Other than your personal appearance (and odour), your business card is often the first impression of your company that a potential client or associate receives. As well as conveying the important contact details, it might also be the only chance you get at that time to differentiate yourself from your competitors with a positive brand image. If you’re wondering whether a crisp and tactile plastic card will impress more than a slightly dog-eared paper card you fish out of your wallet ask yourself this question: would your sister prefer to go out with Brad Pitt or a toothless Bolivian goat herder?

Image sells, but that’s not to say that an amazing paper card won’t sell better than a badly designed plastic card. It’s horses for courses, so when you’re jockeying amongst your competitors for the rich pickings, here are the pros and cons.

Plastic cards are recyclable and durable they’ll survive the washing machine, coffee spilled into your lap, and bending.You can layer different colours and use transparent areas to give real depth to the design, even leaving some areas completely transparent, and you’ll be in a minority if you have them.

However, they’re much more time consuming to design, and more expensive to print, particularly for short runs.You can’t write on them as well as paper cards, and if you don’t round the edges they’re quite sharp. Often thicker than paper cards, you’ll not fit as many in wherever you carry them – be careful not to run out! In many cases inks are mixed by hand so achieving a perfect colour match to printed material is difficult.

So: fantastic or fad? If you’re in an industry where image is important they could be that little extra branding boost that makes the difference. In some respects they’re more functional than conventional cards, and that’s probably what sums it up – who wants to be ‘conventional’ in today’s lightning-paced world?

Forget tearing open gifts found under a Christmas tree and leaving shreds of paper and ribbon everywhere. More and more consumers now reach for letter openers to find gift cards.

The National Retail Federation predicts that consumers will buy nearly $25 billion worth of gift cards this year, an increase of about 34 percent from $18.5 billion in 2005.

Once thought of as impersonal, gift cards will show up under more trees this holiday season. These small pieces of plastic have become today’s flexible, safe and “can’t go wrong” gift item.

Some gift-givers and employers prefer giving cards because they are “safe” purchases that seem more personal than handing someone a wad of cash.

Gift for the picky

“I get a gift card for somebody who’s hard to shop for,” said Lesli Baker of Pleasanton. “People get me gift cards because I’m hard to shop for, and I’m picky.”

For retailers, the gift card boom has come with added benefits such as free money when consumers do not use the cards or extra revenues when shoppers spend more than the value of the card.

“People tend to treat themselves when they use a gift card; they buy a luxury item or a non-sale item,” said Chris Donnelly, a partner focusing on retail with Accenture, a consulting firm. “They also tend to spend more than the total value of a gift. In general, if you’re a retailer, those are both good things.”

Extending shopping season

Selling pricier or full-price goods means larger profits for retailers, but it also means an extended holiday season. Most holiday gift cards are used in January, Donnelly said, so retailers have to keep fresh merchandise in stock.

“Smarter retailers are going to take advantage of (the longer holiday season),” he said. “If someone really wants to treat themselves to a cashmere scarf after the holidays, they can probably sell a lot of those at full price.”

A recent survey of American consumers conducted by Accenture found that 72 percent of respondents have given or received gift cards, and about 36 percent prefer receiving gift cards over other gifts.

“If it’s from my mother-in-law, definitely a gift card,” Baker said. “From my niece, I want her to get me gifts. She’s trendy.”

Cards from stores such as Gap, Target and Nordstrom typically are worth their face value and will not lose value over time.

Gift cards issued by credit card companies such as Visa, MasterCard or American Express carry fees and lose value over time.

Sunvalley mall in Concord, for example, sells an American Express card that can be used at the center or any other shopping centers owned by its parent company, the Taubman Centers. The cards have a $2.50 fee when purchased and lose $2 per month if they are not used within 12 months.

Some cards go unused, and the funds return to the retailer or state governments who categorize them as unclaimed property.

The National Retail Federation reports that in 2005, the average gift card was worth $33.42.

Determining the right amount for a gift card can be tricky. Is $10 too little? Is $100 too much?

“The amount I spend depends on how important the person is to me,” said Michael High of Brentwood.

He said he often buys $50 gift cards. Another gift card buyer, Luis Almeyda of Walnut Creek, said his normal target price is $25. Baker said her cards are normally between $25 and $50. Her mom and in-laws are usually on the top end of the range.

Avoiding the guesswork

Almeyda said he started buying gift cards because it takes the guesswork out of finding the perfect item for someone. High agrees.

“I do buy people gifts when I’m in the mood to shop or I know exactly what they want,” High said.

Some retailers, such as Safeway, Longs Drugs and Nob Hill grocery stores, sell gift cards for other retailers on aisle displays near cash registers and on kiosks.

Pleasanton-based Safeway has deals with 200 other retailers ranging from Nordstrom and Sears to Olive Garden and McDonald’s, according to Safeway spokeswoman Teena Massingill.

She declined to provide specific numbers, but she said that sales from Safeway’s “Gift Card Mall” have grown every year since it was started in 2001; Safeway does receive a percentage of the sale.

Buying a gift card during a trip to the grocery store or drugstore makes buying gift cards even easier, shoppers said.

Pick right store, online option

Nordstrom, Target and Macy’s offer a virtual gift card that can be bought and used online, bypassing the need for a piece of plastic. Some cards, such as the ones offered by Starbucks, are used for gifts and as debit cards by regulars.

Choosing the right store for the right person also is important. Some shoppers prefer stores such as Target, Best Buy or Macy’s because they offer wide selections.

Baker, for example, said she would never buy someone a gift card from Wal-Mart because she does not like the merchandise there.

“I think a gift card is a very dull type of gift,” said Susana Scarborough of Oakland. “It shows no imagination. It’s like saying, ‘Well, I have to do this, but I don’t have time.'”

Corn Card Ready to Replace Millions of Plastic Cards, Including Photo ID’s, Hotel Key-Cards and Gift Cards

Millions of PVC cards are used every day in a plethora of applications and industries – cutting across nearly every social and business sector imaginable. These include photo IDs for schools and companies, membership cards, hotel room key-cards, and gift and loyalty cards. But since their production is dependent on oil, a non-renewable resource, PVC cards adversely affect the environment, both in their manufacture and eventual disposal.

In contrast, Corn Cards are made from corn, a readily available, renewable resource. Key features include:

* Same familiar look and feel of standard white PVC cards.

* Identical quality and durability of printed cards.

* 100% biodegradable and no toxins released when properly disposed.

* Made from special corn type – not derived from corn used in human food supply.

PVC’s use is rapidly declining, as more and more manufacturers and retailers recognize its harmful environmental effects.

“Biobased plastics such as PLA are a safer and smarter choice for our health and environment than PVC, the poison plastic. PVC is the worst plastic, releasing cancer-causing chemicals that poison our air, foul our water, and contaminate our bodies. We commend companies like Advantidge for moving away from PVC and towards safer alternatives such as PLA. When companies put consumers first, opting to prevent harm where possible, we know that progress is being made,” said Mike Schade, PVC Campaign Coordinator for the Center for Health, Environment & Justice, an environmental health grassroots organizing group based in Falls Church, Virginia.

“When you work with some of the country’s largest retailers, most prestigious educational institutions and all levels of government, they rely on our consultation everyday to meet their unique needs,” said Lawrence Grafstein, CEO, Advantidge. “Corn Cards are a major step forward, easily allowing us to proactively assist our customers in addressing their ‘going green’ initiatives.”